Claremont 3D Design Ltd

Chemical System Project Engineering, Management & Technical Deliverables

Portfolio

Examples of work to show range of capabilities, for more detailed presentations including classified Nuclear work please contact us

New Product Install & Integration - Tank Farm to Production

-

New vessel & system design, procurement, oversight of construction & commissioning.

Before:

After:

Replacement Tanker Offloading Bays

-

Bays replaced with new - constructed alongside existing, while bays were still in service, including deluge system revisions.

Before:

After:

Replacement Water Tank & System Mods for Legionella Compliance

Before:

After:

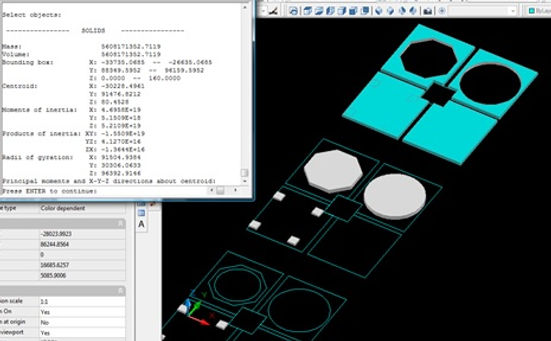

Bund Survey & Volume Calculation

-

Existing bund was not large enough to accommodate vessel volume so the plant had to manage & operate the system to within the calculated volume.

Screenshot of Volume Calc:

Chemical pits & drainage seperation with new pumping systems

-

Existing chemical drain & storage systems required survey, re-mapping, short-term repairs and re-design to effluent treatment.

Survey & example of one system:

After:

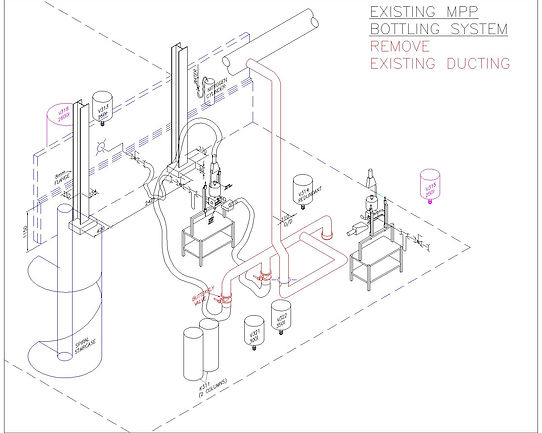

LEV Improvements

-

Redesign of existing systems in co-ordination with client operations team & specialist designer/installer, producing scope of work, contractor selection & management including overseeing instalation & commissioning:

Before - Photos & iso layouts showing existing systems:

Scope of Work iso layouts showing agreed proposals:

Stills from Smoke Test Videos:

Pressure Relief Studies

-

Performed pressure relief studies involving determining the pressure envelope, identifying credible relief scenario's, calculating relief loads for each scenario and determining the Worst Case

-

Sizing the required relief valves' orifice size and developing datasheets for tendering

-

Calculating inlet & outlet pressure drops and reaction forces.

-

Experienced with both Single and 2-phase systems

-

Calculations based on either API 520 / 521, STD 2000 or BS EN ISO 4126 or MerkBlatt depending on Protected Equipment Design Code.

-

Development of the Site Register of Protective Devices

-

Updating FlareNet Model

Training

-

ABB Pressure Relief Sizing

-

DIERS Emergency Relief System Design